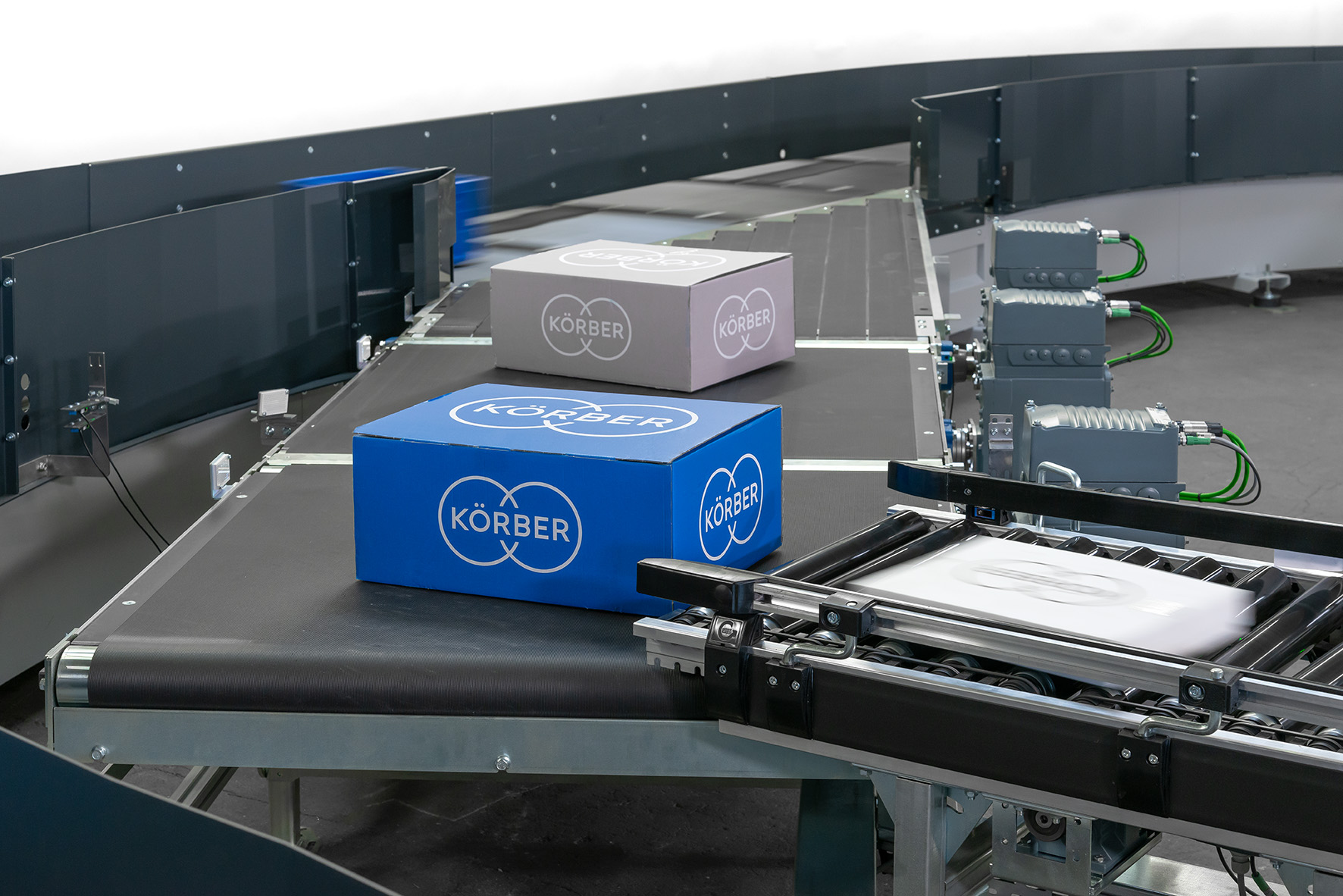

Hamburg, July 1, 2020. Körber Crossbelt Sorter enhances depth and breadth of supply chain solutions with complete materials handling portfolio

Körber, the global supply chain technology leader from software to materials handling automation, today unveils the Körber Crossbelt Sorter. The latest addition to Körber’s portfolio empowers businesses to create truly unified automation solutions to excel in today’s increasingly complex supply chain landscape.

Supply chains must handle more products, more suppliers and fulfill through various channels. Consumer expectations for choice, convenience and speed add to this complexity. To maintain a competitive edge, businesses need automation technologies to handle the evolving challenges of ecommerce and fast moving consumer goods (FMCG). However, many businesses lack a solid strategy and struggle with implementation, integration, and costs. Kӧrber overcomes all of this.

“Körber has the goal of strategically aligning our supply chain technologies and expertise to the needs of our customers and the industry,” says Stephan Göttsche, chief executive officer at Körber Supply Chain – Automation. “The Körber Crossbelt Sorter exemplifies this. One in three companies still manages supply chain processes manually. This is one of many initiatives we are taking to expand our portfolio and capitalize on our 30+ years of expertise in system integration to design automation systems for today and tomorrow’s demands.”

The Crossbelt Sorter seamlessly integrates with any materials handling equipment (MHE) to create unified automation systems. Be it conveyors, shuttles, or beyond, the Crossbelt Sorter uniquely links the MHE of different functional areas – receiving, storage, multi-stage picking, or dispatch. Hence, the Crossbelt Sorter dynamically distributes goods based on any criteria to the proper destination at any stage in the process. Furthermore, the sorter’s modular design enables quick and simple integration with the existing system landscape. The result is a higher level of automation, enabling shorter reaction times, increased efficiency and higher throughput. Examples of success include transport of up to 14,000 containers per hour, carrier changeovers in only 10 minutes, and conveying speeds of 1.8 m/s.

“Conquering today’s supply chain complexities requires higher levels of automation,” said Pieter Feenstra, chief sales officer for Kӧrber Supply Chain – Automation. “Intelligently linking different material handling components is necessary to excel in today’s market. Körber offers the consulting, the solutions, the software and systems integration to make it a reality for businesses of any size.”

The Körber Business Area Supply Chain is part of the international technology group Körber. This includes Aberle, Aberle Software, Cirrus Logistics, Cohesio Group, Consoveyo, DMLogic, HighJump, inconso, Otimis, Langhammer, Riantics and Voiteq. Körber has proven success with thousands of companies worldwide.